This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

Man welded metal thousands of years before the harnessing of electricity transformed welding. The art of joining metal using heat and hammers was one of the first metalworking skills developed after the smelting of humankind perfected iron smelting.

Can you weld without electricity? You can weld without electricity. The methods used before welders had the luxury of electricity are still practiced by some today. There are many ways to perform this process. Electrical welding is only one and is a relatively recent introduction to the process.

Welding with electricity is now the industry mainstay, but many methods of welding without electricity remain popular. Even the advent of space travel introduced a new method of welding without electricity to the metalworking industry. Electricity has certainly made welding easier and more foolproof, but it isn’t necessary to join two pieces of metal.

Welding is an Ancient Craft

When man began smelting iron, the process of joining two or more pieces of metal together became a necessity. The only tools available to these early metal workers were their furnaces or forges and hammers.

The process of heating the metal parts to be joined, coating them with flux material, and then hammering the two parts together until they form a joint along the overlap.

The first forge hammered welds were crude and suffered as much from the quality of the metal as from the little-understood process.

As time passed, knowledge increased until forge welding eventually produces welded metals comparable to anything produced today.

How Do You Weld Without Electricity?

Welding without electricity depends on using various flammable gases to heat the metal to the temperature needed for fusing the joint.

Some methods require explosives and even new welding technologies that require no heat at all (no need for heat resistant gloves).

The Tried and True: Forge Welding

Forge welding is a tried and true method developed over thousands of years of metalworking. Almost every culture that has developed metalworking has employed forge welding as part of their technology.

Many of these cultures raised the art of forge welding to such heights that the quality of their metalwork remains comparable to the best metalwork produced today.

The oldest method of forge welding is the heat and hammer method using hand-held hammers and fire.

At some point, the discovery that adding material called flux between the metals would aid in the welding process. T

he pinnacle of this process was the creation of pattern welding commonly used in creating weapons such as swords.

Today forge welding continues to be popular. Many home and hobby metalworkers routinely use forge welding techniques in their shops to create one-off projects.

The process of forge welding is as much art as it is science.

New technologies in forge welding have emerged. Forge welding is not used just for iron and steel in producing small projects.

Titanium alloys are routinely forge welded. When done properly, a forge weld in some alloys of titanium is stronger than the individual metals.

An advantage of forge welding is the basic nature of the tools and methods. The easy availability of tools puts forge welding well within reach of the home and hobby metal worker.

A forge, either gas-fired or coal-fired, some method of injecting air into the forge, an anvil, and a hammer are all that is required to accomplish a basic forge weld.

A Bit More Modern: Welding With Gas

Another popular method of welding without electricity is gas welding.

The discovery of acetylene in 1836 made gas welding possible, but it wasn’t until about 1900 that technology advanced enough to produce a suitable torch that would allow gas welding.

Gas welding heats the metal at the point of the weld to a temperature at which the metals melt and fuse.

In some instances, extra metal is introduced into the weld using a welding rod. Gas welding has several advantages.

- Gas welding can join dissimilar metals. Welding of ferrous and non-ferrous metals is possible with gas welding.

- The equipment needed to gas weld is easily transportable.

- Equipment costs for gas welding are relatively inexpensive. The low cost of the equipment puts a gas welding rig well within the range of the home and hobby metal worker.

- The basic techniques of gas welding are easy to learn.

There are some downsides to gas welding. The gases commonly used are extremely flammable and come in highly pressurized tanks.

Safety measures must emphasize when using gas welding equipment.

For more detailed information on gas welding equipment and techniques, visit Interesting Engineering.

Things That Go Boom: Welding with Explosives

Explosion welding is another method of joining metals without electricity.

However, this type of welding is well out the scope of the home and hobby welder and rarely occurs outside of highly specialized industrial processes.

The great advantage of explosion welding is the ability to join materials that cannot be joined by more conventional welding processes.

The most common use of explosion welding is to clade carbon steel plates with corrosion-resistant materials such as stainless steel, nickel alloys, and titanium.

Explosion welding even allows welding zirconium to steel plate.

Explosion welding does not depend on heat to create the weld. During World War I, it was observed that shrapnel from exploding bombs and artillery shells stuck to armor plates.

The shrapnel pieces were not just embedded in the armor plate but welded to the surface.

After the war, replication of the process occurred in the laboratory.

With study, the process became understood, patents applied for, and industrial use of the process began.

Explosion welding requires extensive knowledge of explosives and metallurgy.

That requirement and the fact that the explosives used are not available to just anyone without a special license means explosive welding is not a method that home and hobby welders will have in their toolkit.

Cold Welding

During the 1940s, scientists discovered cold welding technology.

The scientists found that two clean flat surfaces of similar material would adhere together if brought into contact in a vacuum.

Unlike fusion welding process that requires heating the metal to a molten phase, cold welding occurs without any form of heat-generating equipment such as torches or electric arcs.

The downside is that cold welding needs a near-perfect vacuum.

Achieving this condition requires specialized equipment far beyond the reach of the home and hobby welders.

The largest industrial use of cold welding is in the creation and construction of the extremely small structure in the nanoscale range.

What Tools Do You Need to Weld Without Electricity?

Two options exist for the home hobby welder who wants to weld without electricity.

Forge welding and gas welding are the two options that most home and hobby welders chose for welding without electricity.

Even professional welders will routinely opt for gas welding when electricity is not available.

What do you need to get set up for forge welding and gas welding in your shop?

Forge Welding Tools

Getting started with forge welding can be a bit daunting. The tools and equipment needed are specialized and, in most cases, not readily available.

However, there is a large community of metalworkers who support the forge welding art, and the internet can aid in sourcing the necessary parts and tools.

The Forge

The forge is your heat source for making your welds.

Forges come in two styles, portable and stationary, and can be fired with coal or with gas.

The critical parts of a forge are the hearth, the tuyere, and a blower. The hearth is where the fire is built if you are using coal as your fuel source.

The tuyere is a valve mechanism that allows you to direct and control the air from the blower into the fire.

Gas fire forges are much simpler and can be constructed easily by the home or hobby metalworker.

There are hundreds of websites and videos on the internet that detail the step by step process of building a gas-fired forge.

The Tools

The necessary hand tools you need to begin forge welding are simple. Most of these tools are readily available in most tool stores.

- The Anvil is the biggest tool in the shop. The anvil is made of steel and has a table for hammering metal. The horn of the anvil sticks out from the table. You use the horn to create bends or shapes. Their weight designates anvils. Common sizes are #150 (150 lbs.), #200 (200 lbs.), etc.

- Hammers come in a wide variety of styles. They can range from small peening hammers to heavy sledgehammers or shop hammers for working large pieces of metal. Forge welding requires at least one heavy flat-faced sledgehammer.

- The metal you handle will be red hot. Tongs are the tool of choice for handling metal straight from the forge and come in many styles of jaws designed for very specific jobs. You will need several sets of tongs in your forge to handle different sizes and shapes of metal. At the least, you will need a pair of flat jaw tongs and a pair of duckbill tongs.

- For yourself, you should have a leather apron. Forge welding generates a lot of sparks and flying bits of metal. These are hot and can cause significant burns on contact. A good leather apron will protect you and your clothing from these flying sparks and metal bits.

- Don’t forget safety glasses, gloves, and a fire extinguisher.

As you progress with your forge welding, you will find that there are many more tools and accessories that you will need.

These are necessary to make good solid forge welds, but they can make your life easier.

Technology has made the forge welders job much less strenuous with the introduction of hydraulic presses and heavy-duty automatic hammers.

These tools take the physical labor out of the forge welding process and are certainly welcome additions to the shop but are not necessary to making good forge welds.

Gas Welding

For the home and hobby metal worked, gas welding may be the option for you. Gas welding is portable and flexible and offers the home and hobby metal workers with more options than just welding.

A gas welding outfit will allow you to not only weld but also to cut and braze metals with no electricity.

There are numerous combinations of gases or other flammable materials used for gas welding. The most popular and the most readily available to the home and hobby metal worker is oxy acetylene.

The basic equipment for oxy-acetylene welding can be purchased affordably at any welding supply shop and even at some of the big box home improvement stores.

The source of heat for welding comes from mixing and igniting two gases at the tip of a welding torch or blowpipe.

The two gases, oxygen, and flammable gas are mixed at the blowpipe and produce an intensely hot flame.

The flame can be adjusted using the valve built into the blowpipe.

Gas Welding Equipment Basics

For novice gas welders, purchasing a kit that contains the required equipment is the best choice.

These kits are economical and readily available from a variety of retailers. Purchasing a kit ensures that the various parts and pieces work together properly.

The kit should contain at least the following items.

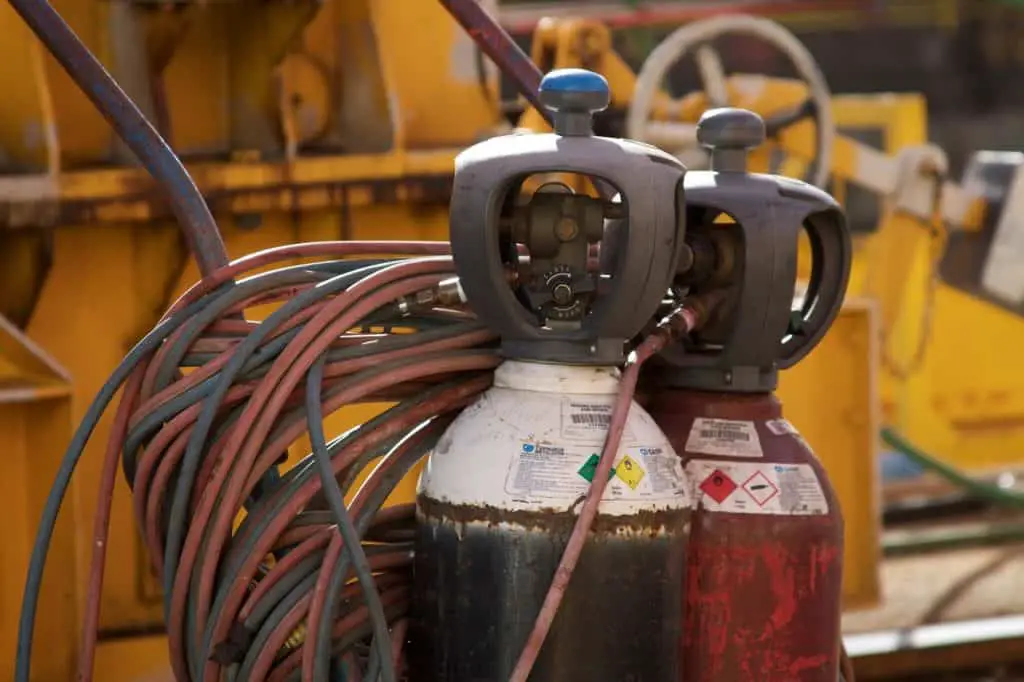

Gas Regulators

The gas regulators attach to the top of the gas bottles used to transport and contain the oxygen and flammable gases.

The regulators function primarily to control the pressure of the gas sent to the torch. The regulators gave valves used to close off the flow of gas.

Regulators have two pressure gauges.

The high-pressure gauge shows the pressure of the gas in the tank, while the operating pressure gauge indicates the pressure delivered to the torch.

This operating pressure is adjusted using the pressure adjusting screw on the regulator.

Hoses

Your gas welding kit needs hoses to deliver the gas from the regulator to the torch.

Typically gas welding hoses are color-coded with red hoses used to carry the flammable gas and a green or black hose used for the oxygen. The hose fittings differ to keep you from attaching the wrong hose to the wrong regulator.

Flammable gas hoses have left-hand threads, and the oxygen hoses have right-hand threads

Torch or Blowpipe

The business end of your gas welding system is the torch, sometimes called a blowpipe. The torch has a valve used to control the mixture of the gases.

Once the gases mix, you can ignite the mixed gas at the tip of the torch, and the flame adjusted using the valves on the torch handle.

A good torch will have interchangeable tips.

Interchangeable tips are important to ensure that you get the best use of your torch.

Selecting torch tips is based on the types you use, the job, and the material.

Tanks and Gas

Tanks for welding gasses are available from the same companies that sell the gases.

You might find a deal on used tanks, but the uncertainty of the condition of the tank is a consideration.

Purchasing a tank from a reputable gas supplier ensures that the tank is in good condition and properly inspected.

Some gas suppliers will rent tanks with a fill-up of gas.

While this might seem economical at first, unless you are using a lot of gas, it may become more expensive over time than purchasing your won tanks.

Welding Cart

A welding cart makes your gas welding rig more portable and safer than simply standing the gas bottles against the wall.

A wheeled cart means you can move the welding rig around your shop or even out into the field.

The cart also protects you and your gas welding rig. The weakest point on the gas bottle is the neck or the place where the regulator connects to the bottle.

Gas bottles are heavy, and when fitted with a regulator and hoses, they become top-heavy and prone to tipping.

Nothing can ruin your day more than having a pressurized bottle fall over and break off the regulator.

Fully pressurized bottles become rockets, and the gas inside can become highly flammable.

Not a situation that anyone wants to find themselves.

Safety Equipment for Welding Without Electricity

Safety equipment needs are as important as the other equipment.

First and foremost, remember that the materials with which you are working or highly flammable and under pressure.

Your protection is your biggest concern. Safety goggles with lenses designed for welding, leather gloves and a leather apron should top your list.

Having a fire extinguisher close by is a necessity as well. Hot metal and flammable gasses can become an instant accident waiting to happen.

Lastly, keep an igniter close at hand.

Trying to light a torch with a cigarette lighter is asking for burned fingers.

A torch igniter will light the torch quickly while keeping your hands clear of the flammable gases.

Gas Welding Options

A gas welding rig offers the home and hobby metal worker several other advantages over other methods of welding, especially those that don’t need electricity.

Cutting metals and brazing metals that don’t lend themselves to welding can add a lot of versatility to your metalworking shop.

Other flammable gases add flexibility to the gas welding rig.

Changing torch tips and regulator setting allows other types of flammable gasses for the welding process. Other flammable gasses are sometimes advantageous depending on the metal with which you are working.

Welding Is Possible Without Electricity!

Welding happened long before the discovery of electricity.

The techniques and methods of welding without electricity are still in use today by both hobby welders and professional fabricators.

New technologies in welding are expanding the horizons of welding without electricity.