This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

Welding is a satisfying and in-demand profession that can lead to a successful life, but there are dangers to welding, which can be overlooked. One danger to welding is inhaling the particles that are present while welding. This can lead to respiratory problems such as bronchitis, airway irritation, pulmonary infections, and lung cancer.

Do welders need Respiratory Equipment? It is critical to use respiratory equipment while welding. Welding releases harmful chemicals into the air, which can contribute to numerous health problems. Using respiratory equipment has benefits, and every welder, especially full-time, should employ respiratory equipment for their safety.

There are several reasons why anyone engaged in the occupation of welding should use respiratory equipment to prevent health problems. It can be a dangerous occupation, so it’s important that safety precautions should be taken to defend the respiratory system.

Why Do Welders Need Respiratory Equipment?

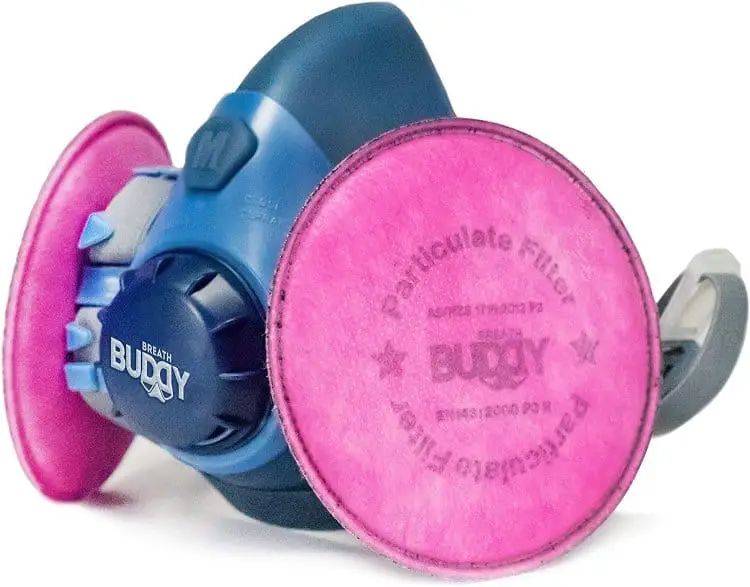

Many hazards come with welding. Just like many other occupations, there is some exposure to risks that must be taken into consideration when performing job duties. One of the biggest being the inhalation of toxic fumes and metal particles in the air. Using a respirator can help prevent you from inhaling these irritants (check out our recommended respirators here).

The following dangers of welding can be harmful if not prevented with respiratory equipment (check out our 9 common welding mistakes article for more):

- Welding fumes: When welding, welding fumes will be released into the air and is the primary airborne containment. These fumes are a complex mixture of small metal oxides. The composition of the welding fumes depends on factors such as the composition of the electrode, the base metal, the surface coatings, and the type of shielding.

- Gases and vapors: When welding, the electrode coatings, fluxes, shielding gases, and surface coatings are burned and exposed to ultraviolet rays. This can cause harmful gases to develop such as carbon monoxide, ozone, nitrogen oxides, gaseous fluoride, and phosgene.

Welding in enclosed areas can be dangerous because the poor airflow gives more exposure to harmful chemicals. In some cases, loss of consciousness or death can occur from inhaling the gases and vapors as a result of welding.

Using respiratory equipment can save your lungs from infection and cancer as welding for 8 hours a day for years on end can cause serious damage. While most welding shops have ventilation that meets safety standards, it is still important to protect yourself from constant exposure.

What Are Long-Term Effects of Welding on Lungs?

According to the Occupational Safety and Health Administration (OSHA), prolonged exposure to the fumes from welding can cause not only lung damage, chronic bronchitis and lung cancer, but also damage to kidneys, the nervous system, stomach, and larynx.

The chances of respiratory damage and other health issues increase significantly when the welding environment is not properly ventilated and/or the welder is a cigarette smoker. These compounding factors significantly increase risk.

There are studies of other potential welding-related dangers, such as the exposure to manganese in welding fumes. Manganese toxicity can result in serious neurological disorders, spasms, and even Parkinson’s disease.

What Kind of Respiratory Equipment Should A Welder Use?

Various respirators can be used to improve the health of the environment while welding. These respirators are typically loose-fitting or tight-fitting.

- Loose-fitting respirators are typically helmets or hoods

- Tight-fitting respirators are face masks that cover the mouth and nose or cover the whole face.

There are two different types of respirators. These are:

- Air-purifying: This style of respirator removes the contaminants from the air. It filters the air and allows you to inhale oxygen without the particles present, which may result from welding. These are often masks or hoods.

- Atmosphere-supplying: This style of respirator is when pure oxygen is supplied, instead of purified air. This style is typically reserved for more toxic environments.

How Do You Use Respiratory Equipment?

There are multiple options for respiratory equipment that can be used for welding. Some of these options are:

- Disposable masks – These masks can prevent fumes and particles from getting in your lungs. They are one-time-use and designed for basic welding in a ventilated area. An N95 mask will meet standards; however, the higher-rated mask, N100, offers better protection.

- Particulate Mold Filter – This charcoal filled filter can help filter the air. They can be worn over the disposable masks, which will add more protection.

- Welding helmets – Some welding helmets offer respiratory equipment. These welding helmets have a hood and face protection. This is a great option for more complex welding, especially with poor ventilation.

What Are Other Hazards of Welding?

Another large safety while welding, in addition to the metal particles that are in the air, is the exposure to radiation. There are also other safety hazards in welding which need to be considered when you are trying to safely weld. Some of the hazards of welding are electric shock, bright lights, radiation, toxic fumes and gases, heat, fire, burns, and noise damage.

There is a lot of safety equipment that should be used while welding, which can help protect your body and skin from the dangerous elements. The many dangers of require certain safety precautions – especially protective equipment.

What Other Safety Equipment Should A Welder Use?

Welding can be a dangerous occupation. The fumes you are exposed to can damage your lungs and failing to use a proper mask can damage your eyes. There is a lot of safety equipment that is recommended for welding. Some of this equipment is:

- Welding helmets – It is important to shield your face from sparks as well as the radiation that is emitted when welding. Failing to use a weldinghelmet can cause damage to your eyes, as well as your face and skin. Check out our recommended welding helmets here.

- Goggles – These can be used in situations when a full helmet is not possible. These are not great to use because they still allow your face and skin to be exposed to the welding. Check out our recommended welding goggles here.

- Hand-held face mask – Some may use a hand-held face mask to block the sparks and radiation. However, the hand used to hold the mask is still exposed to the welding sparks and radiation.

- Hood – Some companies offer a cloth hood that covers you from the shoulders up. They typically come with goggles and an air-purifying mask.

- Safety glasses – While you should always wear a welding helmet or similar, you should still wear safety glasses to protect your eyes from particles that may fly up.

- Gloves – You will need flame-resistant gloves. These can range from light-duty to heavy-duty, depending on the weld. There are also different types of gloves to look for depending on if you are doing TIG, MIG, or solder, other any other type of stick welding.

- Welding jackets- There are welding jackets that can be used to cover your arms and chest. Welders have traditionally worn leather jackets that protect against the sparks, radiation, and heat.

- Aprons and sleeves – These are typically worn beneath the welding jacket to offer an extra layer of protection. Check out our recommended welding aprons here.

- Hats and beanies – A welding hat is typically colorful but great to protect your head from sparks. Some welders wear beanies or sweatbands to protect their face from sweat.

- Boots – Leather work boots are recommended. There are welding-specific boots that offer more protection. You can also wear heat-resistant “leather spats,” which are shoe covers that go over your work boots and protect your feet.

The safety equipment used for welding may be expensive and cumbersome, but your health and safety are of utmost importance. No corners should be cut when it comes using proper precautions. The layers of personal protection available to you should be employed at all times to protect you from the hazards of welding.