This post contains affiliate links to products, services, or education. We may receive a commission for purchases made through links.

Welding is a very dangerous job that needs to be carried out in a thoughtfully and with an eye for safety. When welding, there are many things to think about to be safe on the job. One of the most important safety steps you need to take as a welder is to ensure that your machine is grounded.

But, can you weld without a ground? In short, yes you can weld without a ground, but you are putting your safety at risk. Not only are you putting your personal safety at risk, you are also risking the harm of others, damaging your welding equipment and the object you are working on.

When setting up your welding equipment, you may wonder if you need to ground the equipment or if you can just weld as is, in any setting. This article will explore the process and reason behind the importance of grounding your welder before beginning.

Grounding a Welder

There are different schools of thought when it comes to the necessity of grounding a welder.

Remember safety is the first thing that you need to focus on. Operating a welder without it being grounded is jeopardizing the safety of the operator, building, and anyone around the machine.

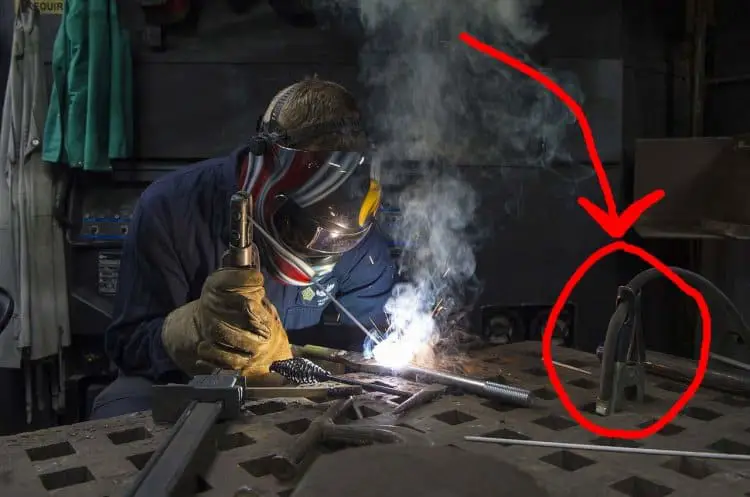

Kevin Caron has a good video explaining how to safely ground to a workbench or your work.

Do All Welder’s Need to Be Grounded?

Knowing the results of choosing not to ground a welder may have you asking the question, do all welder’s need to be grounded?

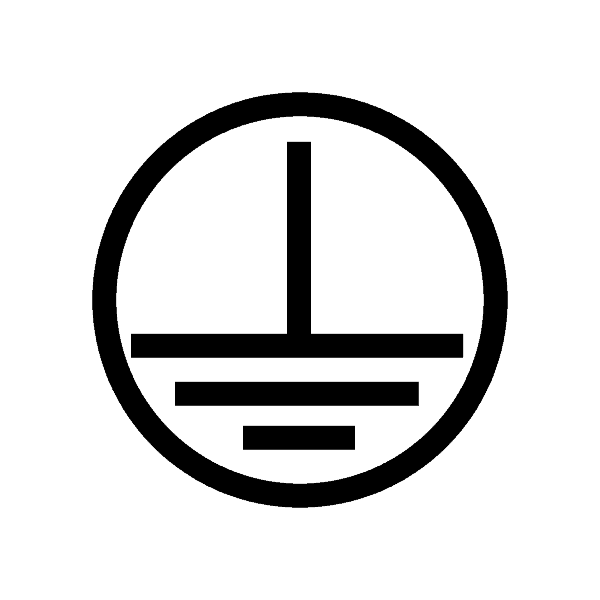

Fortunately, some welders already come with a double insulation, which provides the grounding necessary to safely operate the machine.

If you have a welder that contains double insulation, you do not need to ground the welder.

However, not all welders have this feature. Be certain yours does before assuming. Look for a “box within a box” symbol on the rating plate to verify.

After looking at the rating plate, if you are still uncertain, it is best to speak to a person qualified to tell you the requirements and ratings.

If there isn’t a person that you can ask, always reach out to the company. They will know their products better than anyone.

Small Welders that Plug into an Outlet

If you are operating a small-scale welder that requires 110v, there is more than likely a ground already built into the plug. Make sure you are plugging it into a grounded outlet to ensure the protection is in place.

Never remove the grounding prong on the plug. If you choose to remove the plug, you will be putting yourself, equipment, and location in danger.

How Do I Ground a Welder?

Now that you have read the importance of welding with a grounded machine, you may be asking how to ground a welder.

The good news is that it is very easy to ground a welder, and there are several methods that can be used, some wiser than others.

Remember, if you are searching online for the best method to ground a welder, you are going to come across many different ideas.

These ideas are not all good or bad. It is important that you use your best judgment and consult with an electrician or individual experienced in grounding welding machines.

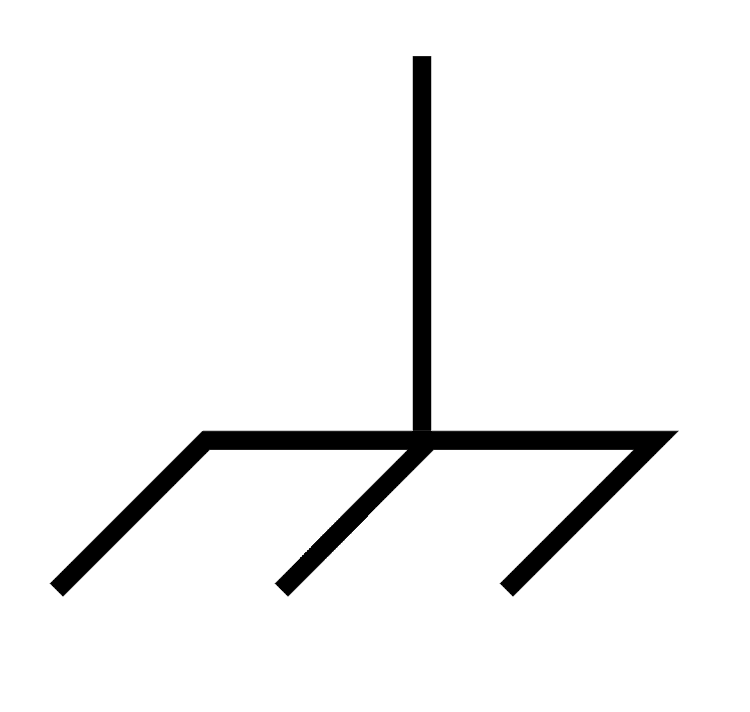

Connect (Ground) to the Earth

The most common method of grounding a welding machine is connecting the ground wire to a metal rod that is in the ground. This is a good method if you are outside with your welding machine.

Connect to a Building Frame

When you are using a building frame as a ground, it is referring to a metal building frame. Make sure the ground connection is separate from the other welding connections when doing this. You would most likely use this for a welder that is immobile.

Extension Cord Grounds

In a pinch, you may choose to use an extension cord as your ground.

This is possible and okay, but you must remember the amount of wear and tear an extension cord goes through. Make sure you are checking the cord often for breaks or cracks.

Can I Attach the Welder to My Vehicle Frame for a Ground?

Looking at the various places you may use your welder, you may be thinking the only metal piece of equipment you have in your vehicle, which has a metal frame. Knowing this, you may think it would be possible to use it as a ground.

You can ground the welder with your vehicle, but there are several precautions that need to be taken. If you choose not to take these precautions, you will risk damaging costly equipment in your vehicle, such as batteries, electronics, and fuel lines.

When using a vehicle as the ground, it is recommended that you disconnect the battery and any sensitive electronic equipment that may be compromised with the high voltage flow.

Again, there are many schools of thought when it comes to attaching a welder to a vehicle frame. I would recommend using this as a final resort, and to proceed with caution.

After reading about the equipment needed and the safety factors of welding with and without a grounded machine, you are now ready to tackle your first welding project.

Please be sure to ask questions when you don’t know the answer. Using the internet is a great resource but is not always the best for accuracy.

When in doubt, contact an electrician or the company that produced the machine you are using.

What are the Risks of Using an Ungrounded Welder?

After reading about how to ground your welder, you are probably still wondering what the risk is if I don’t ground my welder.

I know there are many people that desperately need to save time, and that often means taking shortcuts.

I’ve already expressed the danger you are putting yourself, machine, and equipment/object being welded on, when you choose not to ground, but let’s get more specific.

- A welder uses an extremely high amount of voltage. If you don’t ground your machine and the electricity has nowhere to go to reach the ground, it will ultimately go through you, causing you to be the ground.

- This is particularly dangerous when you are working in wet conditions since water is a natural conductor. Combine this with an ungrounded welder, and you are increasing your shock risk.

- When choosing to weld with a welder that is not grounded, you are also increasing your fire hazard. If the current has no ground wire to go to, it will end up exiting the wires, which could potentially cause a fire.

- You are putting the equipment you are welding at risk. For example, if you are working on a machine that has electrical components, the surge of power can go directly through those components, rendering them useless.

The main takeaway from this article should be that although you CAN weld without a ground, it is not recommended from a health and safety standpoint.

Welding without a ground is increasing your risk for something extremely dangerous and life-threatening to occur.

When weighing the risks of welding with a ground and without a ground, it should be clear that grounding the welder is a significant step that should not be skipped over.

If you feel that you are not electrically savvy enough to do this, spend the extra money, and find someone who is.

If you are welding and feel tiny jolts, even if it isn’t enough to be painful or harmful, stop and check your equipment, including the ground. Remember, you don’t want to be the ground the energy uses to escape.

If you liked this article, you would probably like “Does welding a bolt weaken it?”.